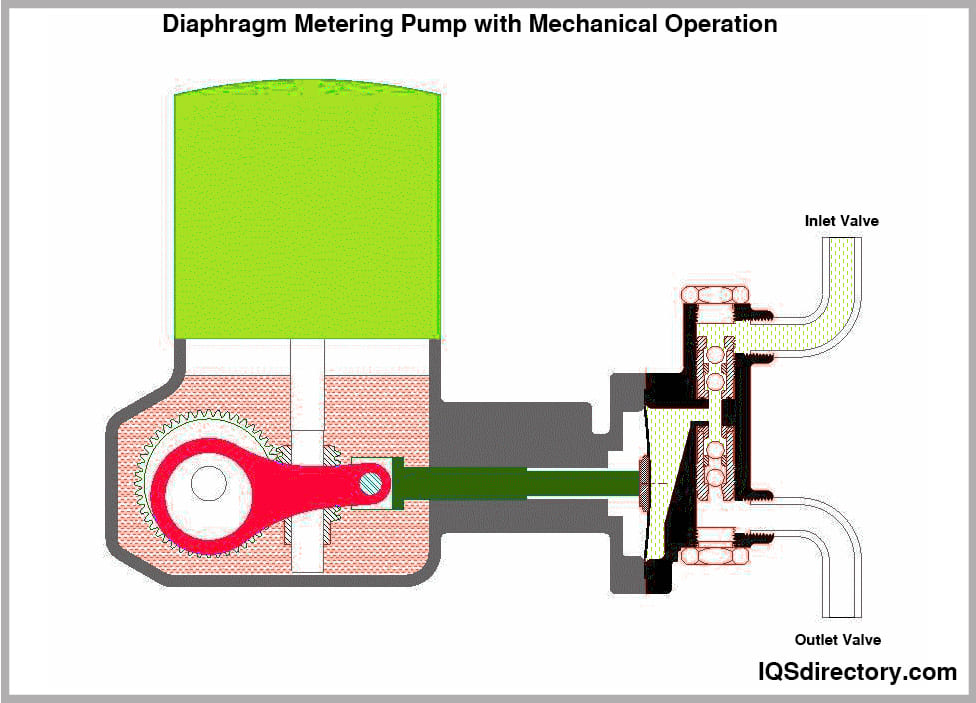

The power drive device drives the fluid delivery diaphragm piston to reciprocate through the mechanical linkage system. It is also called as a membrane pump.

Hydraulic Diaphragm Metering Pump Youtube

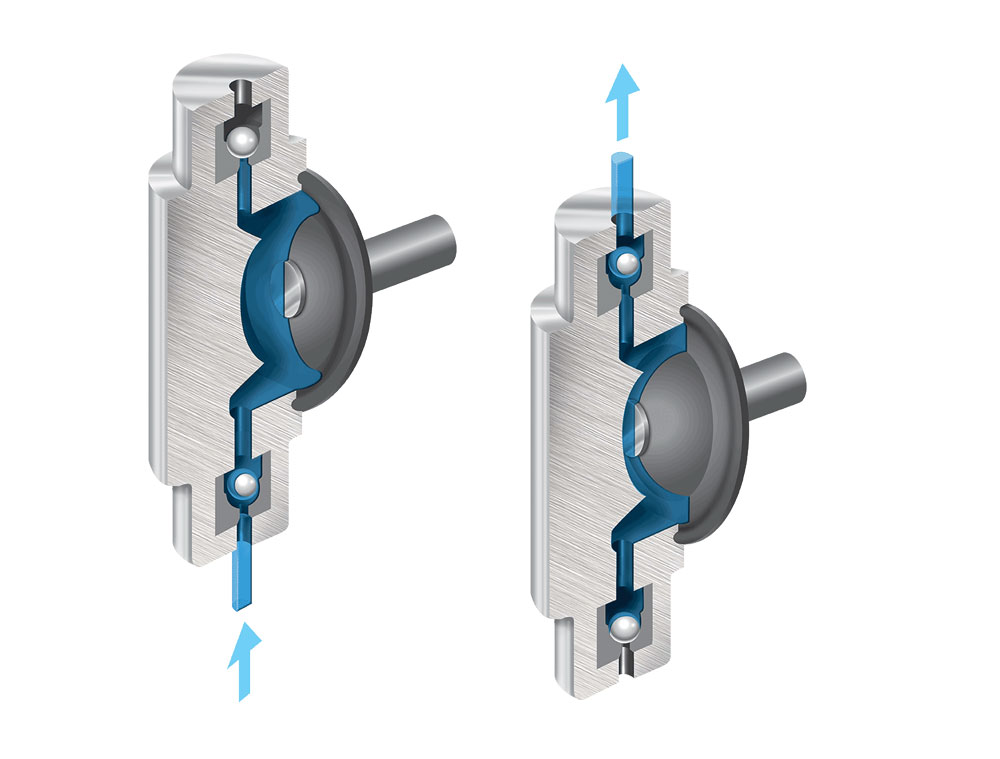

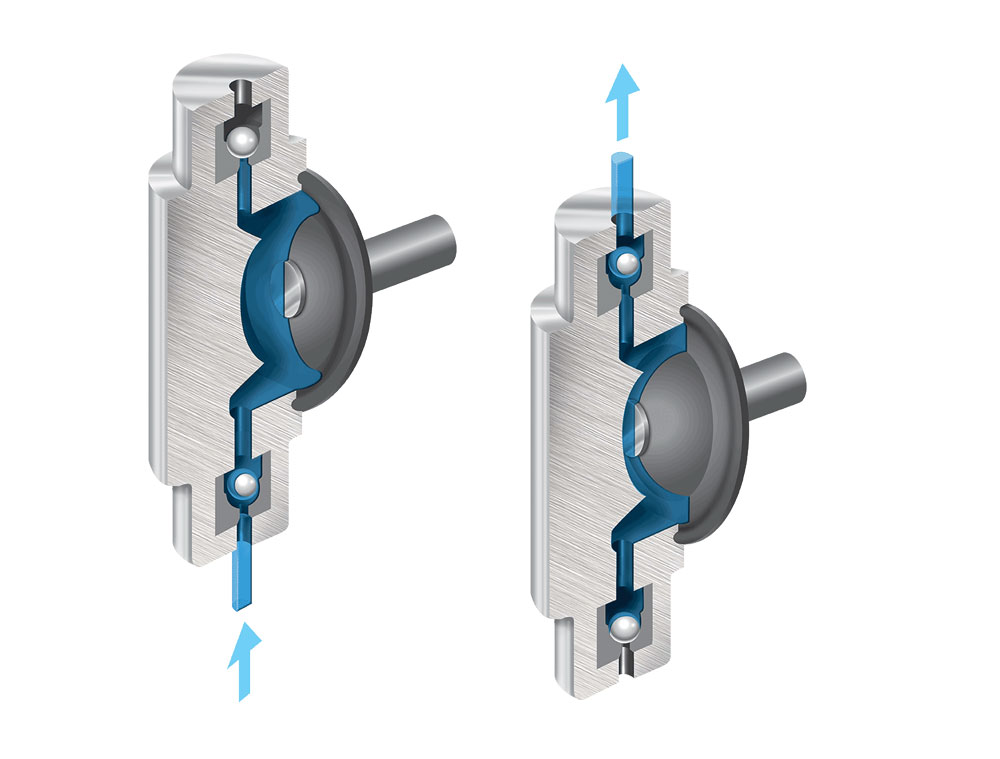

The compressed air pushes diaphragm No2 away from the center block causing diaphragm No1 to be pulled toward the center block.

. Many metering pumps are piston-driven. With recent advances in electronics and control technology gear pumps can be used across a wide range of conditions and have the advantages of a virtually pulse-free flow and an ability to work at high pressures with high viscosity liquids. The accuracy of measurements is 5 and the variation of flow can be as much as 10 when.

CAB controls Hoist Valve. Metering rod 2 fits into the piston. Working principle of diaphragm valve.

Able to transport high viscosity medium abrasive slurry and hazardous chemicals. Dump truck control valve. Piston-driven metering pumps commonly work as follows.

Note the front of the piston or nose has a reduced diameter. As we all know the metering pump is mainly composed of three parts. In pump chamber two the discharge ball valve is.

No dynamic seal no leakage. 1 The front and back movements of the diaphragm are used to change the diaphragm and the pump head causing the ball valve to move up and down forming a phenomenon of vacuum adsorption and pushing to achieve the purpose of liquid transportation. ① When the diaphragm is pulled back the outlet.

These pumps are widely used to handle a wide range of fluids in. Working principle of diaphragm metering pump. Working principle of precision metering pump.

A diaphragm pump is a PD or positive displacement pump. API 6A Valve Control Valve Diaphragm Pump Magnetic Drive Pump Metering Pump Flange Fitting Other Valves. AQUARIUM Air Pump.

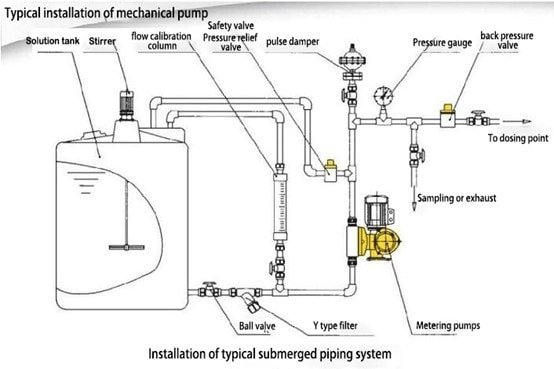

The liquid seal forms 3 where the full diameter of the piston contacts the cylinder. They are the core part of an integrated metering system designed. The maximum outlet pressure is 3MPa and the maximum flow range is 6000 litres per hour.

Under the working pressure of 5 to 8 kg the high-pressure gas in the valve chamber. Traditionally plunger or piston pumps diaphragm pumps or peristaltic pumps are used for metering and dosing duties. Dongou Industrial Zone Oubei Wenzhou Zhejiang China.

Dosing pump also known as dose pump metering pump is a positive displacement pump that is designed to inject a chemical or another substance into a stream of water gas or steam. High tolerance of the PTFE diaphragms. The air diaphragm pump is composed of two parts the air flow structure and the liquid flow structure which are completely isolated by the diaphragms on both sides.

Oilgasworld oilandgaslearningDiaphragm Pump WorkingLIKE COMMENT SHARE SUBSCRIBESUBSCRIBE. Heres a summary of how they work and why theyre the first choice of people who put the emphasis on quality serviceability and economi-cal cost of ownership. When the piston moves forward oil by-passes over the reduced nose through port 4 to the center.

The pistons forward movement transmits hydraulic force. Power drive fluid delivery and adjustment control. Principle is similar for all PULSA Series metering pumps.

The diaphragm piston will be. The air source pressure only needs to be more than two kilograms per square centimeter to work. This pump works with using a blend of the reciprocating action of a rubber Teflon diaphragm otherwise thermoplastic appropriate valves on any face of the diaphragm to push a liquid.

Hollow piston 1 reciprocates within a cylinder. When pressurized diaphragm No1 reaches the end of its stroke the movement of air is switched by the air valve from diaphragm No1 to the back of diaphragm No2. Piston pumps are positive displacement pumps which can be designed to pump at practically constant flow rates averaged over time against a wide range of discharge pressure including high discharge pressures of thousands of psi.

Metering pumps are typically small and provide extremely precise flow rates for maximum control. There is a piston sometimes called. The pump drive mechanism transmits a reciprocating action to a piston operating in a hydraulic reservoir.

Metering Pumps Types Uses Features And Benefits

Diaphragm Pump Dosing Metering Pump Working Animation Youtube

Introducing The Seko Ms1 Mechanical Diaphragm Dosing Pump Youtube

Industrial Dosing Pumps Volumetric Pumps Comparison Pcm

What Is A Dosing Pump Types Advantages Applications

Dosing Metering Pump Working Principle Haosh Pump

0 comments

Post a Comment